Creating new potentials to bring TKV Mechanical to approach the industrial revolution 4.0

06/05/2022Over the past years, the mechanical units of the Vietnam Coal and Mineral Industries Group (TKV) have continuously promoted investment in equipment, technological innovation and production lines to increase mechanical engineering capabilities. create and localize products to meet coal production needs. However, the results are not as expected, while the potential of TKV Mechanical Engineering is still high. In order to fully exploit the existing advantages of a developing member, give TKV Mechanical a new potential, and approach the industrial revolution 4.0, it is necessary to clearly define the capacity and potential. capabilities and development opportunities of TKV Mechanical Engineering in the current context. Therefore, in order to become “Mechanical Engineering” and one of the main industries in the multi-industry business strategy, TKV Mechanical must have products bearing its own brand, must reach out to dominate the domestic market and creating a premise for export, strongly proliferating endogenous technology and increasing the ability to assimilate imported technology.

VMC E500-1 side loader – one of the products with high localization rate of TKV Mechanical.

Opportunities and challenges from Industry 4.0

The 4th Science and Technology Revolution was formed based on combining digital with high technologies to create smart technologies such as 3D printing, robotics, artificial intelligence, and Internet of Things. objects (IoT). Future manufacturing will combine the fields of physics, digitalization and biology, network of virtual worlds (software, networks) and real world (machines and devices)… close together. The convergence of top-notch technologies allows optimal use of resources, saving labor, saving investment, saving time,… in the process of research – manufacturing technology and organization. production organization and is seen as an opportunity and a challenge for the economic sectors of developing countries. If grasped and oriented, it will be an opportunity to accelerate development speed; on the contrary, if not grasped, the risk of technical backwardness and economic backwardness will be present in the immediate future.

TKV Mechanical Engineering is a mechanical engineering industry serving the field of mining and processing of solid minerals with its own unique characteristics that are no exception to that rule, including challenges and opportunities for development.

The most basic challenge is that the current technological and technical background of TKV Mechanical is still quite outdated, the technology level is mainly still at the level of the 2nd Industrial Revolution with many difficulties and problems: (i) No core technology, no mastery of material technology; (ii) Processing is mainly in the form of single units and small-scale; (iii) Sector linkage, regional linkage is still limited; (iv) The scale and potential of enterprises are limited, lack of competitiveness in the region; (v) The competition is getting fiercer, not only in the industry, but also in the region and internationally.

Besides, Industry 4.0 also brings TKV Mechanical many opportunities. With the increasingly strong development of digital technology, communication, and specialized software, it will be both a promoter and a support for manufacturing enterprises to change production methods in the direction of increasing efficiency. , Cut the cost. The outstanding development of processing technology and the modernization of technological equipment will create good opportunities for TKV Mechanical to access modern science and technology, optimize the production process, and facilitate technological innovation. technology and have many opportunities to participate in regional and global supply chains. TKV mechanical engineering as well as other enterprises will benefit from the suppliers (technology, equipment, technical materials) of developed economies when competing with each other to increase quality, schedule and cost.

Step by step mastering design and technology

The Group’s mechanical engineering division currently has 12 units, including 11 mechanical manufacturing companies and 01 specialized research institute, the Institute of Energy and Mining Mechanics, with a total workforce of 3,150 people. The division’s revenue is about 5,000 billion VND per year.

Most of the Mechanical Manufacturing Plants of TKV were built from the 1960s to the 1970s with the help of the former Soviet Government. Most of the technological devices are old universal machining equipment with a low level of accuracy.

According to the previous development planning and orientation, TKV Mechanical is designed, invested in equipment and production processes mainly serving the repair of specialized equipment in open-pit mining and processing. coal transformation.

In the last 10 years, TKV has advocated accelerating the transformation from Repair Mechanics to Manufacturing Mechanics, step by step mastering design and technology to manufacture imported replacement parts and equipment. The production units of TKV Mechanical have invested and equipped with many modern and synchronous technological equipment in precision machining stages and are gradually automating the production stages.

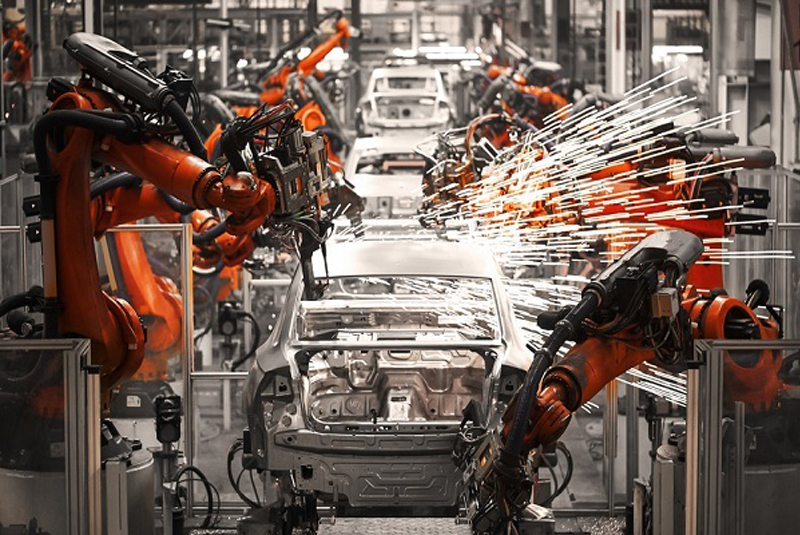

Uong Bi Automobile Mechanical Joint Stock Company manufactures and assembles excavators.

Some recent import-substituting manufactured products can be mentioned, such as:

(i) Fabrication and assembly of equipment: EKG-10 excavator with bucket capacity up to 10m3; Trucks with a tonnage of up to 35 tons; Combai AM-50Z excavator; Explosion-proof hydraulic excavators in pits with bucket capacity from 0.15 to 0.6 m3; Electric locomotives use explosion-proof batteries used in underground mines with traction force up to 120 kN; Types of Drilling, Excavation, Transporting equipment used in tunneling mechanics.

(ii) Fabrication of self-propelled anti-rigs, movable frame racks in synchronously mechanized furnaces; types of poles, hydraulic cylinders for underground coal mining with a diameter of up to 200mm.

(iii) Building new watercraft, including dry cargo ships up to 15,000 DWT.

(iv) Manufacturing and assembling specialized vehicles for the industry. In which there are mixer trucks loaded with industrial explosives; vehicles carrying explosives; vehicles transporting people, equipment, and materials in steep kilns.

(v) Design and manufacture of electrical equipment: substations up to 6,300 kVA- 110 kV; high quality electrical cabinets, transformers, starters from explosion room to 1,250 kVA-6/0.4 kV.

(vi) Design and manufacture of equipment in the field of transportation and screening: Explosion-proof conveyors with a capacity of up to 3×630 kW, explosion-proof conveyors with downward slope, using regenerative braking with capacity up to 2×200 kW; explosion-proof rake chutes with capacity up to 250 Ton/hour; sieves classified up to 800 Ton/hour; systems of threshers, wet and dry sieves, bucket chambers of all kinds used in mineral extraction plants.

(vii) Gradually manufacture and export spare parts and equipment used in mining and mineral transportation to the international market, typically: Wear-resistant parts of Combai machines; Ball bearings, battery shafts in large capacity transport equipment; Roller conveyors;…

In addition, many equipment that was previously imported from developed countries such as Poland, Russia, Japan and China has been partially localized by TKV Mechanical, manufacturing all kinds of spare parts. to be proactive in production and reduce equipment investment costs. Currently, TKV Mechanical is completing the product standard system, calculating the localization rate and gradually paying attention to the branding work to help the market have more information to identify the products. mechanical brand TKV.

Modern machinery is invested by Automobile Industry Joint Stock Company – Vinacomin, in order to meet the manufacturing and repair capacity.

Maintain production through the pandemic

2021 is the second year the economy is greatly affected by the Covid-19 pandemic, in which mechanical engineering is a manufacturing industry that has suffered double impacts from the decline in market demand due to reduced production in other economic sectors. exports, and at the same time suffers additional impacts because the supply of materials and spare parts, especially imported ones, tends to be scarce and unstable in price. With TKV Mechanical, the Covid pandemic has a double impact on production and business results. In which, the biggest impact is the supply of imported materials and spare parts, which is affected both in terms of progress and price stability. Besides, many economic sectors adjusted to reduce output, leading to a decrease in supply in the market, leading to high production costs.

The production and business results of TKV Mechanical in 2021, basically still ensure the growth in sales revenue targets, but the efficiency indicators are significantly reduced. Total revenue in 2021 of the whole Division (11 units) reached VND 5,441.73 billion / VND 4,038.26 billion of the plan (plan), reaching 134.8% of the year plan and equaling 122.9% of the revenue realized in 2020 The average salary of the whole Group is 9,635 thousand VND/person/month, reaching 112.8% of the plan and equaling 103.7% compared to 2020. The proportion of average income growth is much lower than the growth rate. The corresponding revenue correctly reflected the increased value of revenue due to the increased value of cost cost.

High and unstable raw material prices lead to increased financial costs, some small-scale units have a lot of influence on production capital. The costs incurred related to the cost of disease control, testing, production organization 3 on the spot, … affect the production and business efficiency of enterprises. Therefore, the profit before tax of the Mechanical sector in 2021 is estimated at 44,820 million VND, reaching 117% of the plan and equaling 103.2% compared to 2020.

Continue to build TKV Mechanical for Safe – Sustainable – Effective development

Aware of changes in the macro environment in the coming period when Vietnam promotes the process of industrialization and modernization and strengthens international integration, Vinacomin soon organized a study to re-evaluate the current situation of enterprises. , analyze strengths and weaknesses to find development opportunities in the next period, which is reflected in the TKV Mechanical Development Strategy for the period of 2021-2025, with a vision to 2035.

The domestic market of TKV Mechanical in the next phase is oriented to change and develop with the following main features:

- Continue to build TKV Engineering for Safe – Sustainable – Efficient development and associate with TKV’s development plan. Ensuring production capacity to meet the requirements of TKV and gradually reaching out to the foreign market.

- Rearrange production in the direction of specialization, invest in innovation and strengthen the manufacturing and repair capacity of equipment for the main production areas of TKV. Specializing in the repair of machinery and equipment, linking the use of techniques, technology and other technical services.

- Strengthening the cooperation between Consulting – Design – Manufacturing in the country, transferring advanced technology from abroad in combination with human resource training. Promote capacity development in the fields of consulting, design, and scientific and technological research. Promote, strengthen and expand cooperation in product development to serve the needs of units in TKV, other economic sectors and export.

Specific targets on mechanical engineering, striving to meet the demand for mechanical spare parts of production units in TKV with the rate: by 2025, 75 ÷ 80% of the demand will be achieved; by 2030 reach ≥ 85%; By 2035, it will reach ≥ 90% of the demand. To meet the demand for equipment and synchronous lines in underground coal mining in TKV with the rate: by 2025, it will reach 50 ÷ 60% of the demand; by 2030 reach ≥ 75%; By 2035, it will reach ≥ 85% of the demand. For open-pit mining equipment (coal and minerals of all kinds), by 2025, strive to meet 100% of the demand for medium and long-distance trucks, special-use vehicles (carrying explosives, transporting chemicals, transporting water, etc.) , excavators are powered by electricity of units in TKV; meet the demand for equipment and synchronous lines in coal sieving and processing of units in TKV with the rate: by 2025, reaching ³ 80% of demand; by 2030 reach ≥ 85%; By 2035, it will reach ≥ 90% of the demand. For equipment and synchronous production lines in mineral processing, strive to meet the needs of the units in TKV with the rate: by 2025, it will reach 40 ÷ 50% of the demand; by 2030 to reach ≥ 60%; By 2035, it will reach ≥ 70% of the demand. In the field of coal-fired power, to meet the needs of coal-fired power producers in TKV for dust filter equipment, cooling water pump, system of equipment for receiving, transporting and storing fuel (coal, stone) lime) with the rate: by 2025 reaching 40 ÷ 50% of the demand; by 2030 to reach ≥ 60%; By 2035, it will reach ≥ 70% of the demand.

Regarding repair services, implement 100% of the plan to repair, middle and overhaul technological equipment in coal mining, processing and transportation throughout the Group right from 2020. Strive to participate and increase the proportion repair of technological equipment of other production fields of TKV (such as thermal power, manufacturing, etc.)

Leaders of TKV Group inspect mechanical products manufactured by Automotive Industry Joint Stock Company – Vinacomin.

Orientation for development solutions

In order to help TKV Mechanical confidently participate in Industry 4.0 confidently and soon achieve the expected results in the coming period, TKV will continue to strengthen training and retraining of human resources, focusing on improving the quality of key management staff of the enterprise; technical force and a team of experts in the fields. New recruitment goes hand-in-hand with screening, training/retraining to improve the quality of technical labor, and supplement the currently lacking/weak technology groups. Focus on developing a team of technical workers capable of accessing new technologies and modern equipment.

In addition, it is promoting mechanization – automation – computerization, continuing the investment program to modernize equipment and technology, raise the level of automation and strongly apply information technology in the industry. all production and business activities. Parallel investment between technological equipment and specialized software, especially software to support product design and inventory management. Effectively exploit and use the invested equipment.

Review and improve technological processes in production, complete and supplement economic and technical norms to optimize costs in production and improve labor productivity. Increase investment in research, design, manufacturing and testing of new products. Promote the application of research results through science and technology projects to transform into commercial products with good competitiveness on the national and regional scale.

By Tapchicokhi

Must Read

2023 PARTICIPANT LIST

[Seminar] INDUSTRIAL METROLOGY

MTA Vietnam 2022 Webinar

ADB is optimistic about Vietnam’s economy

MTA Vietnam 2021 x Bystronic Webinar

CONFERENCE SERIES

ONLINE BUSINESS MATCHING PROGRAMMES

You may be interested in

REPORT ON THE PRODUCTION AND BUSINESS TRENDS OF THE PROCESSING, MANUFACTURING INDUSTRIES IN THE FIRST QUARTER OF 2024 AND FORECAST FOR THE SECOND QUARTER OF 2024

Industrial production in the first two months of the year increased by 5.7% compared to the same period

Việt Nam có thể trở thành ‘con rồng AI’

Vietnam is ready to welcome the wave of investment in smart manufacturing chains.

Humanoid robot converses with OpenAI language AI

Boeing supplier greenlighted to build $20M plant in Vietnam

Vietnam is a potential market for companies engaged in the manufacturing of agricultural machinery and equipment

‘The Giant’ Goertek is expected to invest over 6,800 billion VND in Vietnam to expand production. Which locality will be chosen?