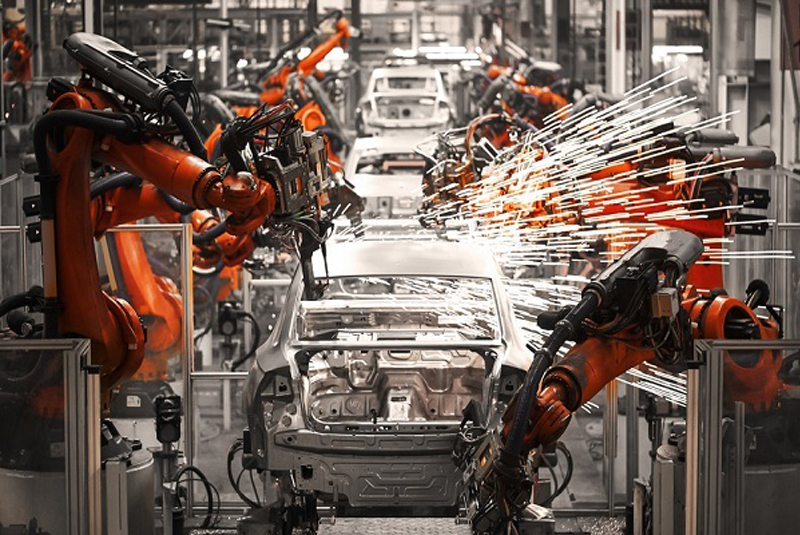

Product supply for the manufacturing industry: Linkage is indispensable

31/03/2022Although there are many policies to encourage domestic enterprises to participate in the production chain of multinational corporations in the manufacturing sector, the majority of products of enterprises are limited in price and quality.

At the seminar “Development of linkages between Vietnamese enterprises and multinational companies in the manufacturing industry” organized recently by the Trade Promotion Department (Ministry of Industry and Trade) in cooperation with the ASEAN-Japan Trade, Investment and Tourism Center, Ms Truong Thi Chi Binh – Vice Chairman, General Secretary of Vietnam Support Industry Association (VASI) – pointed out: Price competition is a stressful and difficult issue, Vietnamese enterprises’ products are now about 20% higher than other suppliers.

“In fact, when entering Vietnam, multinational corporations either carry, or have, suppliers around the globe. These suppliers are experienced, have depreciated equipment and machinery and have advanced production networks with low cost, high output. Meanwhile, domestic enterprises are weak in governance, production is not lean, leading to very low price competitiveness ” – said Ms Binh.

VASI’s survey data in 2021 shows that only about 300 domestic enterprises are currently level 1 suppliers for multinational corporations in Vietnam, distributed mainly in Hanoi, Ho Chi Minh City Pointing out the limitations of Vietnamese suppliers, Mr Nguyen Trung Hieu – Head of Business Planning and Foreign Affairs Department (Toyota Motor Vietnam Company) – said that Vietnam is weak in the raw materials industry (steel, plastic), the level of production techniques is not high, the small market size… these factors cause the high cost of manufacturing components. Currently, the electronics industry imports nearly 90% of its components. Automobile manufacturers and assemblers must import more than 70% of components, buy-in Vietnam about 10%…

In order to become a supplier to multinational corporations, in addition to the price problem, domestic enterprises face difficulties in capacity building to reduce costs and move forward in the supply chain, difficulty to increase production scale, high production site costs and lack of processing stages to have complete assemblies. On the side of multinational corporations, there is no clear localization plan, the market capacity is small, unstable, so there is not enough motivation to find local suppliers…

Policies for the development of the manufacturing industry are not as concerned as they are today. However, the implementation of some policies is slow, even, there are policies that almost no agencies or localities have implemented.

Therefore, “soon bringing policy to life is what enterprises want to facilitate investment in production” – VASI representative said. Ms Binh also made many recommendations to improve the linkages between Vietnamese enterprises and multinational corporations, further developing the Vietnamese manufacturing industry.

In particular, emphasizing the capacity building of small and medium-sized enterprises to meet the requirements of global supply chains; prioritizing and encouraging multinational companies and FDI companies to implement localization through incentive policies on tax, labor, R&D… In addition, it is necessary to promote support activities and linkages between Vietnamese manufacturing industry enterprises and FDI companies; support the training of highly qualified human resources to meet the requirements of the value chain…

Early implementation of support policies is a necessary condition for Vietnamese enterprises to have the foundation, investment and production conditions, become suppliers for multinational manufacturing industry corporations.

Source: Bao Cong Thuong

Must Read

2023 PARTICIPANT LIST

[Seminar] INDUSTRIAL METROLOGY

MTA Vietnam 2022 Webinar

ADB is optimistic about Vietnam’s economy

MTA Vietnam 2021 x Bystronic Webinar

CONFERENCE SERIES

ONLINE BUSINESS MATCHING PROGRAMMES

You may be interested in

Impressions Of The Conference “3D Metal Printing: From Potential To Application Reality For Professional Manufacturing In Vietnam”

Discover The Seminar “Digital Transformation: Reducing Technology Waste”

Experience At Talkshow “World Class Manufacturing: How To Get There From Here”

Inside The Seminar “Promoting Vietnam’s Production Transformation Towards Smart Production”

Looking Back At Talkshow “How To Improve Business Collaboration And Funding Capacity For Manufacturing Firm”

Talkshow “World Class Manufacturing: How To Get There From Here”

Conference “Accelerating Vietnam’s Manufacturing Transformation Towards Smart Production”

Talkshow “How To Improve Business Collaboration And Funding Capacity For Manufacturing Firm”